ความร่วมมือระยะยาวระหว่าง Pollson และ BJ-TECH & HP ได้ผลักดันให้เกิดการอุตสาหกรรมของการผลิตสารเพิ่มประสิทธิภาพกาว (Adhesive Additive Manufacturing - AM) และประสบความสำเร็จในการผลิตจำนวนมาก

ไม่เหมือนกับเทคโนโลยี AM อื่น ๆ การพ่นกาวโลหะไม่จำกัดอยู่แค่การสร้างแบบจำลองหรือการผลิตในปริมาณเล็กน้อย เนื่องจากเป็นกระบวนการที่อาศัยการเผาหลอม ชิ้นส่วนที่เสร็จแล้วจะมีคุณสมบัติที่เหมาะสมสำหรับการใช้งานจริง ชิ้นส่วนตัวอย่างแทบจะตรงกับชิ้นส่วนซีรีส์สำเร็จรูป ซึ่งหมายความว่ากระบวนการนี้สามารถทำให้เกิดการพิมพ์โลหะ 3D ที่ขยายได้ โดยสามารถสร้างรูปร่างที่ซับซ้อนที่สุดได้อย่างแม่นยำ - ไม่เพียงแต่ในระดับอุตสาหกรรม แต่ยังอยู่ภายในกรอบเวลาและต้นทุนที่กำหนด

การเผาอัดแบบ AM ต้องการความรู้เชี่ยวชาญในระดับสูง ซึ่งก็เป็นความเชี่ยวชาญของบริษัท GKN Additive เช่นกัน โดยอาศัยความเชี่ยวชาญนี้ บริษัท (ซึ่งมีสำนักงานใหญ่อยู่ที่เมืองบอนน์ ประเทศเยอรมนี และฐานการผลิตอยู่ในสหรัฐอเมริกา เยอรมนี และจีน) สามารถตรวจพบปัญหาที่อาจเกิดขึ้นล่วงหน้าและรู้วิธีป้องกันไม่ให้เกิดปัญหาเหล่านั้นตั้งแต่แรกเริ่ม

เราให้บริการทุกขั้นตอนของการพัฒนาผลิตภัณฑ์ AM ในอุตสาหกรรม ตั้งแต่การออกแบบผลิตภัณฑ์ ไปจนถึงการพิมพ์ 3D การเผาอัด และการตกแต่ง

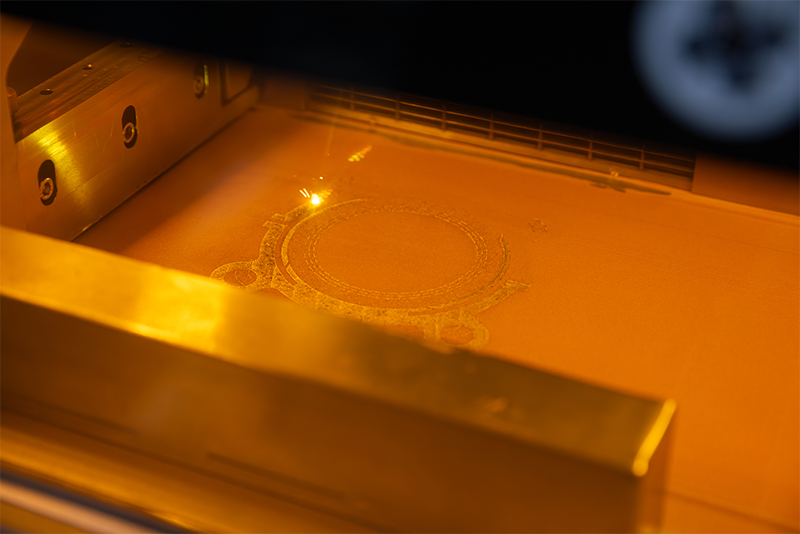

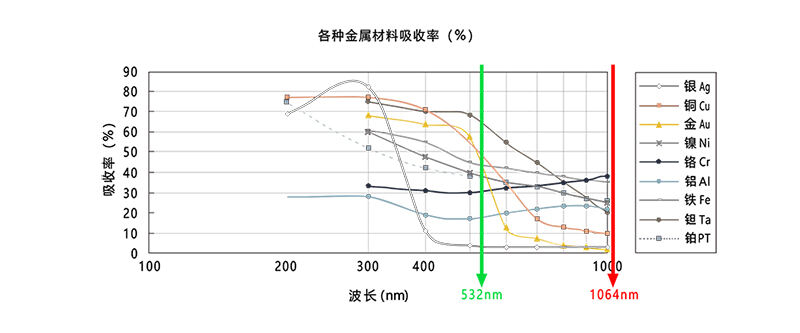

โซลูชัน SLM ของ Pollson โดยใช้เลเซอร์สีเขียวกว้างความยาวคลื่น 532nm มีคุณสมบัติของความยาวคลื่นสั้น, พลังงานสูง และคุณภาพลำแสงสูง ตัวเลือกพลังงานเลเซอร์รวมถึง 500W, 700W, 1000W และ 2000W ทำให้เป็นโซลูชันการหลอมอุดมไปด้วยประสิทธิภาพสำหรับวัสดุสะท้อนสูงและโลหะทนไฟ เช่นทองแดง, ทอง, พลาตินัม, อะลูมิเนียม, เงิน, ทาลเลียม และทังสเตน

อัตราการดูดซึมของโลหะส่วนใหญ่ต่อเลเซอร์จะสูงขึ้นเมื่อความยาวคลื่นสั้นลง แต่มีข้อขัดแย้งตรงที่หากความยาวคลื่นสั้นมาก การสร้างเลเซอร์พลังงานสูงพร้อมรักษาคุณภาพลำแสงสูงนั้นมีความยากทางเทคนิคมากขึ้นสองเท่า เลเซอร์สีเขียวเป็นทางเลือกเดียวในปัจจุบันที่สามารถบรรลุประโยชน์หลายประการ เช่น ความยาวคลื่นสั้น, พลังงานสูง และคุณภาพลำแสงสูงได้พร้อมกัน

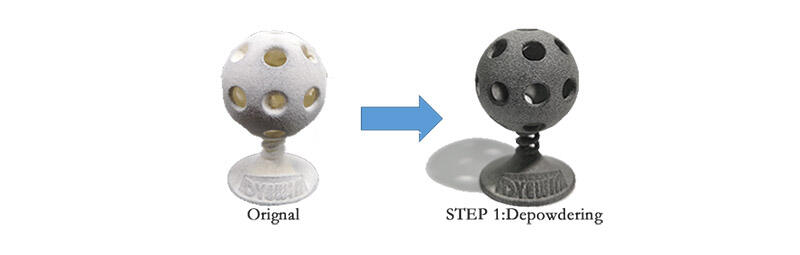

เครื่องกำจัดผงแบบอัตโนมัติป้องกันการระเบิด DYEWIN สำหรับการกำจัดผงเฉพาะทาง เช่น SLS, MJF และอื่นๆ สามารถกำจัดผงจากชิ้นส่วนการพิมพ์ 3D ด้วยผงได้อย่างมีประสิทธิภาพสูงในลักษณะการประมวลผลแบบกลุ่ม ซึ่งช่วยเพิ่มประสิทธิภาพการกำจัดผงและลดต้นทุนได้อย่างมาก เครื่องนี้ควบคุมโดยหน้าจอสัมผัสและแสดงผลด้วยพารามิเตอร์ดิจิทัล เพื่อเพิ่มความฉลาดของอุปกรณ์และความแม่นยำในการทำความสะอาดผง นอกจากนี้ยังมีตะกร้าขนาด 70 ลิตร สำหรับจัดการชิ้นส่วนการพิมพ์ 3D ได้มากขึ้น

1. ใช้กุญแจเดียวในการเริ่มต้น ระบบการบูรณาการระหว่างแมนนวลและอัตโนมัติ

2. การกำจัดผงพิมพ์ 3D อัตโนมัติแบบกลุ่ม

3. ทำความสะอาดผงอย่างสม่ำเสมอและหลีกเลี่ยงความเสียหายของชิ้นส่วน

4. การกรองด้วย pulsed filtration ทำให้การกรองฝุ่นสะอาดและเป็นมิตรต่อสิ่งแวดล้อมมากขึ้น

5. ใช้เวลา 5-15 นาทีต่อรอบ เทียบเท่ากับความเร็วในการประมวลผลของเครื่องทรายแรงดันสูงแบบแมนนวล 3-4 เครื่อง มีประสิทธิภาพสูง

6. อุปกรณ์ใช้ส่วนประกอบป้องกันการระเบิดเพื่อเพิ่มความปลอดภัยในกระบวนการล้างผง

| ประเภทเครื่องจักร | AUTO-JET C 700 |

| วัสดุพ่นทราย | กระจกแก้ว |

| เวลาในการล้างผง | 5-15 นาที |

| ความสามารถในการกำจัดผงต่อรอบ | สูงสุด 75% ของงานสร้างแบบเต็มของ EOS P396 หรือ HP MJF Fusion 4200 |

| ปริมาตรตะกร้าหมุน | 70L |

| ขนาดพื้นที่ทำงาน | 1120*980*1230mm |

| ขนาดเครื่อง | 1480*1580*1880mm |

| น้ำหนักเครื่อง | 300 กก |

| หัวฉีดอัตโนมัติ | 2 ชิ้น |

| หัวฉีดด้วยมือ | 1 ชิ้น |

| ไม้ النفังไอออนกันระเบิด | 2 ชิ้น |

| หัวฉีดความเร็วสูง | 1 ชิ้น |

| ความต้องการอากาศอัด | แห้ง/ไม่มีน้ำมัน |

| การใช้ลมอัด | ≥2.4m3/นาที |

| ความจุของเครื่อง | 1.1kw |

| ข้อกำหนดพลังงาน | 220V~50Hz |

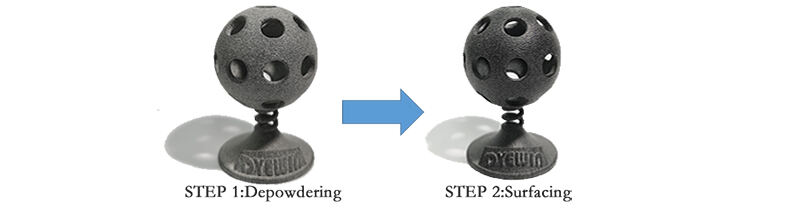

DYEWIN AUTO-JET P 700 อุปกรณ์บำบัดผิวแบบอัตโนมัติสำหรับงานพิมพ์ 3D โพลิเมอร์ ซึ่งเป็นอุปกรณ์ผิวหน้าสำหรับงานพิมพ์ 3D มืออาชีพ โดยผ่านการพ่นทรายพิเศษของ DYEWIN สามารถปิดรูพรุนบนพื้นผิวของการพิมพ์ได้อย่างมีประสิทธิภาพ เพิ่มผลลัพธ์ทางสายตา ปรับปรุงความทนทานและการเงาของพื้นผิว เป็นส่วนสำคัญในการรับประกันคุณภาพการย้อมสี อุปกรณ์นี้ควบคุมโดยหน้าจอสัมผัสและแสดงด้วยพารามิเตอร์ดิจิทัลเพื่อเพิ่มความชาญฉลาดของอุปกรณ์และความแม่นยำของการบำบัดผิว นอกจากนี้ยังมีตะกร้าขนาด 70L เพื่อดำเนินการกับชิ้นส่วนการพิมพ์ 3D ได้มากขึ้น

ข้อดีทางเทคนิค

1. ความหยาบของผิวลดลง 50% และความเสียดทานและการเงาของผิวชิ้นส่วนได้ปรับปรุงอย่างมาก

2. การกำจัดฝุ่นจากไส้กรอง สามารถกรองฝุ่นได้อย่างมีประสิทธิภาพ สะอาดและเป็นมิตรต่อสิ่งแวดล้อมมากขึ้น

3. การไอออนไฟฟ้าแรงดันสูงสามารถกำจัดประจุไฟฟ้าสถิตจากห้องทำงานและพื้นผิวชิ้นงานได้อย่างมีประสิทธิภาพ

4. ติดตั้งด้วยระบบแยกพายุหมุน ช่วยให้ทำความสะอาดสิ่งเจือปนและฝุ่นในวัสดุทรายพิเศษได้ดีขึ้น เพิ่มอัตราการใช้วัสดุและลดต้นทุน

5. จัดการกับวัสดุ PA12, PA11, PA6, TPU และอื่นๆ ได้อย่างมีประสิทธิภาพ

| ประเภทเครื่องจักร | AUTO-JET P 700 |

| วัสดุพ่นทราย | DYEWIN Special Blasting Material |

| เวลาในการเคลือบผิวต่อรอบ | 5-15 นาที |

| ความจุในการเคลือบผิวต่อครั้ง | สูงสุด 75% ของงานสร้างแบบเต็มของ EOS P396 หรือ HP MJF Fusion 4200 |

| ปริมาตรตะกร้าหมุน | 70L |

| ขนาดพื้นที่ทำงาน | 1120*980*1230mm |

| ขนาดเครื่อง | 1480*1580*1880mm |

| น้ำหนักเครื่อง | 300 กก |

| หัวฉีดอัตโนมัติ | 2 ชิ้น |

| หัวฉีดด้วยมือ | 1 ชิ้น |

| หัวฉีดไอออนอัตโนมัติ | 2 ชิ้น |

| หัวฉีดความเร็วสูง | 1 ชิ้น |

| ความต้องการอากาศอัด | แห้ง/ไม่มีน้ำมัน |

| การใช้ลมอัด | ≥2.4m3/นาที |

| ความจุของเครื่อง | 1.1kw |

| ข้อกำหนดพลังงาน | 220V~50Hz |

เครื่องย้อมสี DYEWIN แบบอัจฉริยะเป็นอุปกรณ์เฉพาะทางสำหรับการย้อมสีชิ้นส่วนการพิมพ์ 3D โพลิเมอร์ เครื่องนี้ควบคุมการทำงานด้วยการสัมผัสหน้าจอเพียงปุ่มเดียว และกระบวนการย้อมสีทั้งหมดเป็นระบบอัตโนมัติ ไม่จำเป็นต้องมีการแทรกแซงด้วยมือในกระบวนการ กระบวนการย้อมสีทั้งหมดมีประสิทธิภาพสูงในการย้อมอัตโนมัติ และสามารถนำชิ้นส่วนที่สะอาดออกได้หลังจากกระบวนการเสร็จสิ้น โดยการควบคุมอุณหภูมิสูง แรงดันสูง และการเพิ่มอุณหภูมิ สีสามารถซึมเข้าสู่ชิ้นส่วนการพิมพ์ 3D ได้อย่างเต็มที่ เพื่อให้มั่นใจว่าชิ้นส่วนการพิมพ์และกระบวนการย้อมสีของชิ้นส่วนมีความสม่ำเสมอและเหมือนกัน DW-50 มีปริมาตรการย้อม 50 ลิตร เหมาะสำหรับลูกค้าที่มีความต้องการการผลิตแบบกำหนดเองจำนวนมาก เช่นโรงงานทำแม่พิมพ์ ลูกค้าปลายทาง เป็นต้น

ข้อดีทางเทคนิค

01. สารย้อมสีที่พัฒนาขึ้นเองผ่านมาตรฐานความปลอดภัยของของเล่นยุโรป EN71

02. เหมาะสำหรับ SLS/MJF/SLA

03. กระบวนการย้อมสีอัตโนมัติโดยไม่ต้องมีการแทรกแซงด้วยมือ

04. ความคงทนของสีสูงและพื้นผิวสม่ำเสมอ

05. สี RAL และ PANTONE สามารถปรับแต่งได้

| ประเภทเครื่องจักร | DW-50 |

| เวลารอบการย้อมสี | 1.5-2.5 ชั่วโมง |

| ความจุในการย้อมต่อรอบ | สูงสุด 75% ของงานสร้างแบบเต็มของ EOS P396 หรือ HP MJF Fusion 4200 |

| ปริมาตรการย้อม | 25L/37.5L/50L |

| ระดับการย้อม | 0.1-0.2มม. |

| อุณหภูมิในการย้อม | 110-130℃ |

| สีมาตรฐาน | 12 สี (HP MJF เฉพาะสำหรับ 7 สี) |

| ขนาดส่วนประกอบสูงสุด | φ380*300mm |

| เทคโนโลยีการสนับสนุน | SLS/MJF/SLA |

| ข้อกำหนดพลังงาน | 3P 380V~50Hz |

| ความจุของเครื่อง | 7kW |

| แหล่งข้อมูล | อากาศอัดแห้งและไม่มีน้ำมัน 2bar |

| แนะนำให้ใช้น้ำอ่อน | |

| ขนาดเครื่อง | 1250*850*1050mm |

กระบวนการหลังพิมพ์ 3D เมทัล MP30

โซลูชันการประมวลผลหลังพิมพ์ 3D เมทัลแบบมืออาชีพ สามารถขัดผิวโลหะ สามารถปรับปรุงความหยาบของผิวได้ 1-4μm รองรับเทคโนโลยีการพิมพ์ 3D โลหะหลายประเภท เช่น SLM การสร้างรูปแบบโดยอ้อม เหล็กกล้าไร้สนิม อัลลอยด์ไทเทเนียม และวัสดุอื่น ๆ