Долговремениот партнерски одnos меѓу Pollson и BJ-TECH & HP го подстапил индустријализацијата на лепенчевата адитивна производња (AM) и постигна масовна производба.

Засупрот на другите технологии за AM, металната лепенчева спреј емисија не е ограничена само на прототипирање или маломасштабна производство. Како процес базиран на спечивање, завршените делови имаат карактеристики кои се прилагодливи за практично употребување. Примерочните делови почти потпuno се соодветствуваат со серијните делови, што значи дека овој процес може да постиgne масовно 3D печатење на метали, точно воспроизводејќи најкомплексни форми - не само на индустријална скала, но и во рамките на потребното време и costa.

Синтерингот baziran на AM бара значителен број на професионални знаења, што е и експертизата на компанијата GKN Additive. Со оваа експертиза, компанијата (штабирана во Бон, Германија, со производствени бази во САД, Германија и Кина) може да ги забележи потенцијалните проблеми напред и да знае како да ги спречи од настанување од самото почеток.

Ние ги нудиме сите чекори на циклусот за развој на индустријски продукти AM, од дизајн на продукт до 3D печатење, до sinistering и завршување.

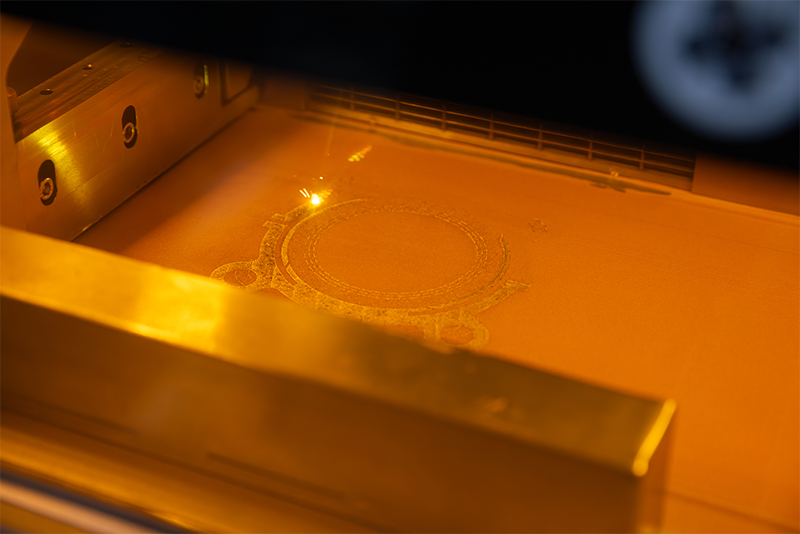

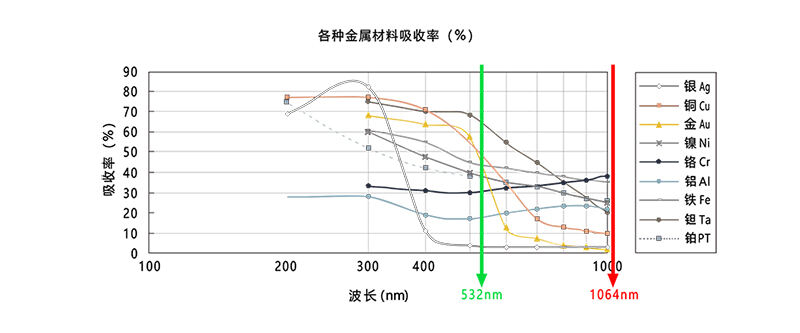

Pollson SLM решение користејќи 532nm дужина на зелениот лазер, тоа има карактеристики на kratка dужина, висока моќ и висок квалитет на луч. Опции за моќ на лазер вклучуваат 500W, 700W, 1000W и 2000W, што го прави идеалното решение за спаивање на материали со висока рефлектирање и огнепрочни материали како што се мед, злато, платина, алуминиум, сребро, тантал и волфрам.

Степенот на аспирација на повеќето метални материали кон лазери е поголем при кратки дужини на талас; противречноста е дека таласната дужина е екстремно кратка. Додека се осигурува висок квалитет на луч, техничката трудност при создавање на лазери со висока моќ се удвојува. Зелениот лазер моментално е единствената опција која може да постигне многу предности како што се кратка таласна дужина, висока моќ и висок квалитет на луч.

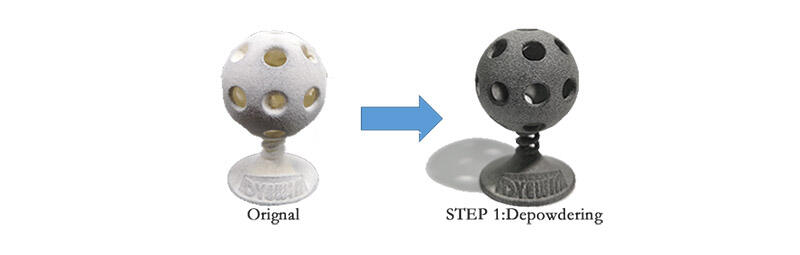

Експлозивна автоматско опрема за отстранување на прах DYEWIN SLS, MJF и друга професионална опрема за отстранување на прах за прахови 3D печатени делови може автоматски да отстранува прах во серии со висока ефикасност, што може значително да ја подобри ефикасноста на отстранувањето на прах и да намали трошоците. Уредот се работи со додирен заслон и се прикажува со цифренi параметри за подобрување на интелигенцијата на уредот и точноста на очистувањето на прах. Опремето е комплетирано со кош од 70Л за обработка на повеќе 3D печатени делови.

1. Еден клуч за старт, интегриран ручен и автоматски режим

2. Групно автоматско отстранување на порошок од 3D печатење

3. Равномерно чистење на порошок и спречување на штета на деловите

4. Пулс филтрирање, чистење на прах е чисто и више екологично

5. 5-15 минути циклус, еквивалентно на брзината на обработка со 3-4 ручни песочни машини, висока ефикасност

6. Уредот користи експлозивни дела за значително подобрување на безбедноста при чистење на порошок

| Тип на машина | AUTO-JET C 700 |

| Материјал за песочење | Стаклено жарче |

| Време на циклус за отстранување на порошок | 5-15мин |

| Способност за отстранување на прашини со една работна тура | До 75% од целосната производствена работа на EOS P396 или HP MJF Fusion 4200 |

| Запремина на вртечката кошарка | 70L |

| Димензиите на работното простор | 1120*980*1230мм |

| Димензии на машината | 1480*1580*1880мм |

| Тежина на машината | 300кг |

| Автоматски Боркадид Нозилки | 2 Комплети |

| Ручни Боркадид Нозилки | 1 Парче |

| Експлозивно-безбеден Јонизиран Джет Стик | 2 Комплети |

| Шлозови со висока брзина | 1 Парче |

| Потреба за компресиран воздух | Сушо/Без масло |

| Потрошувачки на компресиран воздух | ≥2.4m3/min |

| Капацитет на машината | 1.1KW |

| Потреба за енергија | 220V~50Hz |

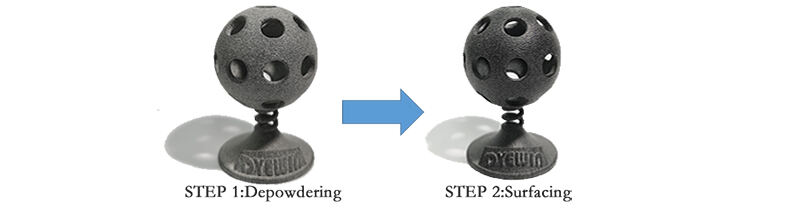

DYEWIN AUTO-JET P 700 автоматско експлозивно-безбедно опрема за површинска обработка при полимерна 3D штампа, професионална опрема за површинска обработка. Преку експлозив DYEWIN специјален пясок ефективно се затвараат порите на површината на штампата, визуелни ефекти, подобрува се издржливоста и sjaj на површината, што е важен дел од jam зголемување на квалитетот. Уредот е оперативен со додирен екран и прикажуван со цифрични параметри за да се подобри интелигенцијата на уредот и прецизноста на површинската обработка. Освен тоа, е опреќан со кошче од 70Л за обработка на повеќе 3D штампени делови.

Технички предности:

1. Грубоста на површината се намалува за 50%, а површинското изношување и блистанje на деловите се значително подобри.

2. Отстранување на прашини од филтерски елемент, ефективно филтрирање на прашини, чистач и поеколошвено.

3. Високото наструјување може да отстрани статичката електричност од работната камера и површината на работниот предмет.

4. Опремен со циклонски сепаратор, подобро чисти незадоволивите материјали и прашините во специјалните пясъчни материали, што зголемува употребата на материјалите и намалува цената.

5. Ефективно обработува PA12, PA11, PA6, TPU и други материјали.

| Тип на машина | AUTO-JET P 700 |

| Материјал за песочење | DYEWIN Special Blasting Material |

| Време за циклус на површинска обработка | 5-15мин |

| Капацитет за површинска обработка за еден тур | До 75% од целосната производствена работа на EOS P396 или HP MJF Fusion 4200 |

| Запремина на вртечката кошарка | 70L |

| Димензиите на работното простор | 1120*980*1230мм |

| Димензии на машината | 1480*1580*1880мм |

| Тежина на машината | 300кг |

| Автоматски Боркадид Нозилки | 2 Комплети |

| Ручни Боркадид Нозилки | 1 Парче |

| Автоматски ионизирани водени џези | 2 Комплети |

| Шлозови со висока брзина | 1 Парче |

| Потреба за компресиран воздух | Сушо/Без масло |

| Потрошувачки на компресиран воздух | ≥2.4m3/min |

| Капацитет на машината | 1.1KW |

| Потреба за енергија | 220V~50Hz |

DYEWIN интелигентен машин за бојување е професионален апарат за бојување на полимерни делови од 3D штампа. Машината контролира једноставна операции преку тачкаен екран, а целот процес на бојување е автоматизиран. Во процесот не е потребна ручна интервенција. Целот процес на бојување е високо ефикасен во автоматско бојување, и чистите делови можат да се извадат после завршувањето на процесот. Преку контролата на висока температура, висок притисок и зголемување на температурата, бојата може потполно да се вклопи во 3D штампаниот дел, за да се осигури еднаквост и конзистентност на бојувањето на деловите. DW-50 е комплетиран со капацитет за бојување од 50Л, соодветен за клиенти со масовни потреби за персонализација, како што се фабрики за прототипи, крајни клиенти итн.

Технички предности:

01. Саморазвивени бои кои минуваат ЕУ стандард за безбедност на играчки EN71

02. Одговара за SLS/MJF/SLA

03. Автоматскиот процес на бојување без ручна интервенција

04. Висока стабилност на бојата и еднакъв површинен изглед

05. РAL и PANTONE бои можат да се персонализираат

| Тип на машина | DW-50 |

| Време за циклус на бојување | 1.5-2.5 Часови |

| Способност за цревање по рун | До 75% од целосната производствена работа на EOS P396 или HP MJF Fusion 4200 |

| Запремина на цревање | 25L/37.5L/50L |

| Длабочина на цревање | 0.1-0.2mm |

| Температура на цревање | 110-130℃ |

| Стандардна боја | 12 бои (HP MJF Само За 7 Бои) |

| Максимална големина на дел од | φ380*300mm |

| Технологија за поддршка | SLS/MJF/SLA |

| Потреба за енергија | 3P 380V~50Hz |

| Капацитет на машината | 7KW |

| Ресурси | Сушав и безмаслен компресиран возење 2bar |

| Препорачливо користење на мека вода | |

| Димензии на машината | 1250*850*1050mm |

Металска 3D печат пост-обработка MP30

Професионално решение за пост-обработка на металска 3D печат, може да полира метална површина, може да ја подобри бурливоста на површината од 1-4μm. Поддржува разни металички 3D печат технологии, вклучувајќи ги SLM, непрякaпно формирање, титаниум спојови, нержавен цинк, алуминиум спојови и други материјали.