3d Printing is a cool, creative way to design and create just about anything. You can start making all sorts of amazing things from a computer and a special printer along with some special materials, all of it works together to create three-dimensional objects, or 3D for short. It’s like magic: Your ideas are suddenly no longer just ideas, but they come to life before your very eyes. Isn’t that amazing? What, exactly, is 3D printing? Well, it’s a way of manufacturing stuff that involves piling on layers of material, one on top of the other, until you have the whole object. All this is easy to understand if you visualize it like building a tower of blocks, where each block is a layer. Because a computer program provides step by step instructions to the printer, it knows exactly what to print. 3d printing technology has existed for some time now but only recently really gained popularity and much as a common knowledge among the general people.

With the increasing number of 3D printing users, the technological developments have been plentiful. slowly but surely, the materials used to create these 3D objects have been improving. For instance, some materials are now lighter or stronger than ever. The printers themselves have also gotten faster and more accurate, so they can make things more quickly and better details. Thanks to these advances, individuals can produce far larger and more complex products than ever previously. Imagine—more creative opportunities.

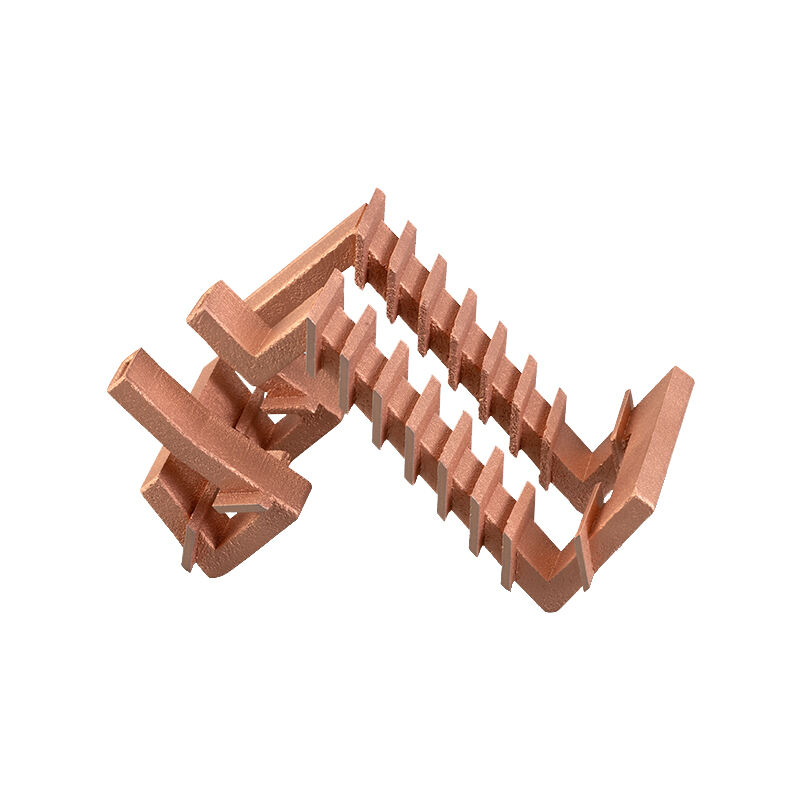

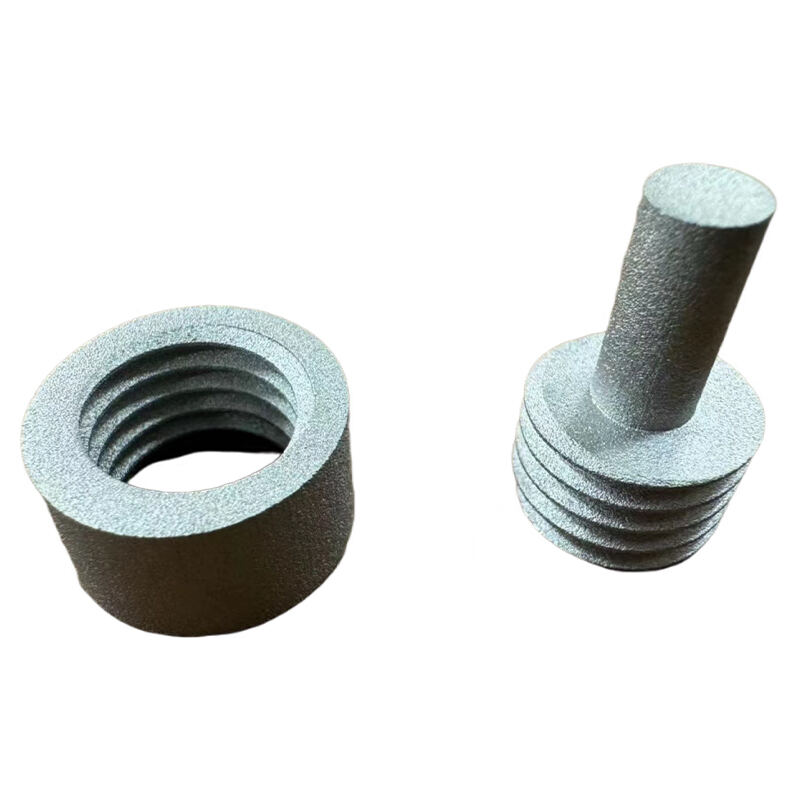

There are many ways to do 3D printing, but one of the most common methods used is SLM, which stands for selective laser melting. SLM is unique in that it utilizes a powerful laser to melt and fuse small particles of metal powder. Unlike other forms of 3D printing, this process produces objects that are extremely strong and versatile, allowing for the rapid production of components, parts, and even tools.

SLM has revolutionised the world of 3D printing in several key aspects due to their ability to create such high-strength items. SLM is simply an advanced form of 3D printing, more commonly known as additive manufacturing, enabling the formation of objects that are considerably stronger. It presents new opportunities in many fields, from airplanes, which require strong materials, to medicine, in which strong and precise pieces can make a difference for doctors and patients.

Now, details on how exactly SLM works. Using SLM for 3D printing, the printer begins by depositing a thin layer of metal powder. This layer is essentially a fine dust. After that, a laser goes in and melts the powder in different places, which fuses or adheres it together. After that, the printer puts down another thin layer of powder and repeats. This process continues layer by layer until the object is completed and ready for use. SLM is super cool, because the laser can be very precisely controlled, and very fine details can be made, in a way that is very similar to a detailed sculpture.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.